Kalundborg Symbiosis: Companies Co-Locate for Sustainability Leave a comment

Quick hits:

- Recycling hospital plastics isn’t easy is because, often, the recyclers simply aren’t near hospitals.

- We’re taking a step outside of packaging to look at an example of the symbiotic and efficient nature of co-located facilities.

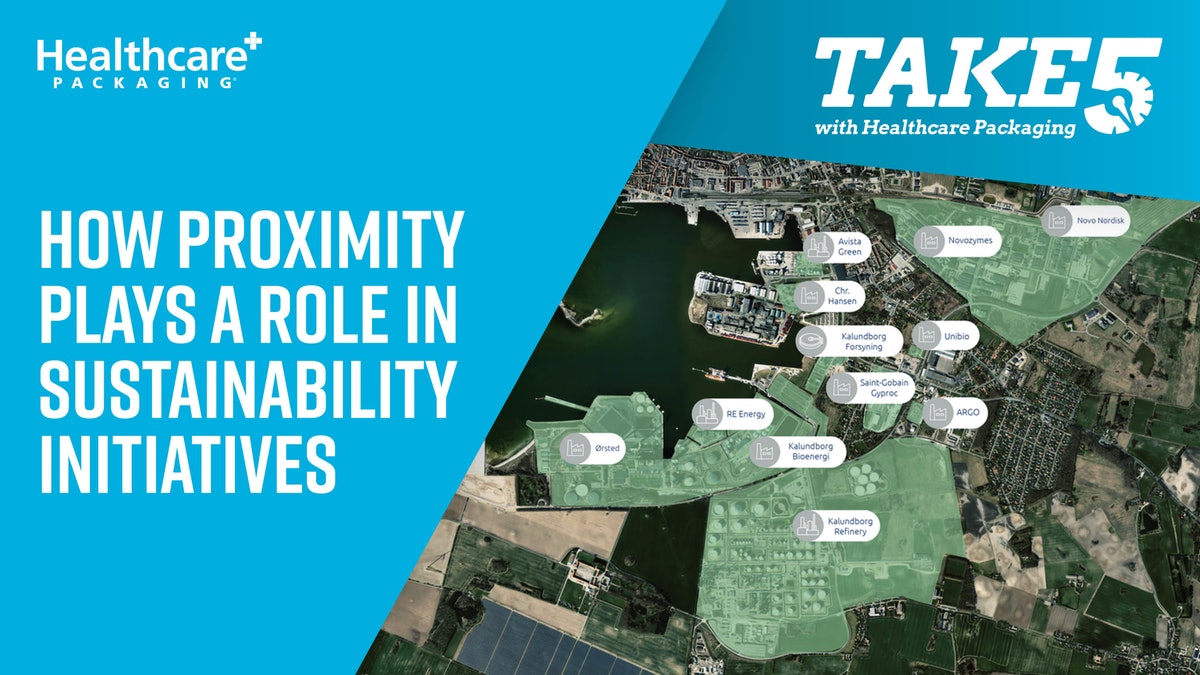

- Kalundborg Symbiosis is an eco-industrial park in Denmark where 13 companies across sectors collaborate to make the best possible use of each other’s by-products and share resources—this includes energy, water, and materials.

- The industrial symbiosis reports that sustainability and profit go hand in hand – something they want to be the next normal.

Listen to the story here:

|

Read the transcript below: |

Hi, I’m Keren Sookne with a Take Five video for Healthcare Packaging. Today we’re talking about how proximity plays a role in sustainability efforts.

At the[PACK]out conferencein Austin, TX, in May, Samantha Smith, Director of Medtronic’s newly created Sustainability Design Center, explained during a panel that one reason why hospital recycling isn’t easy is because often the recyclers simply aren’t near hospitals. They can’t do a milk run to come in and pick up the material on a daily basis—the medical packaging material is going to build up at the facility.

Moving a large volume of hospital plastics just doesn’t make sense for a variety of reasons right now—it’s an expensive hassle to move, it’s difficult to collect and sort and store in already compact footprints, and there’s a carbon footprint associated with long transport distances.

At this point, our recycling infrastructure in the U.S. just isn’t there in many municipalities and just like with consumer recycling, it’s going to have to be efficient for these busy hospitals if it’s gonna become the norm.

So today, we’re taking a step outside of packaging to look at an example of the symbiotic and efficient nature of co-located facilities.

Kalundborg Symbiosis is an eco-industrial park in Denmark where 13 companies across sectors collaborate to make the best possible use of each other’s by-products and share resources. This cooperation began over 50 years ago, and has grown over time.

As the Symbiosis site explains, “companies work together across sectors to share excess energy, water, and materials, so less goes to waste. As public and private companies are physically connected, one company’s surplus of resources adds value to another.” More than 20 different streams of excess resources flow between the companies, creating a symbiosis of resource exchange, adding more resilience and profit to the partners.

Not only are there tangible sustainability benefits, but the Symbiosis model also bolsters trust and innovation within the community. As they say, “It benefits the people such as employees, students, and researchers… and the climate. We are working together to reduce thousands of tons of CO2 emissions each year.”

They add that sustainability and profit go hand in hand – something they want to be the next normal.

So, let’s talk healthcare applications at the industrial park.

- The Novo Nordisksite in Kalundborg, which produces insulin, uses steam from the power plant in the park—the heart of the network—to sterilize equipment. In December, they announced plans to construct three new manufacturing facilities as well as expand one the existing facilities at the site.

- Also in 2021, Christian Hansen joined Kalundborg Symbiosis. According to the news release last year, they purchased production facilities with the aim of producing HMOs (Human Milk Oligosaccharides), which are a special group of complex carbohydrates for use in infant formula. Production is expected to start in 2023, after the facilities are refurbished and expanded.

Now, I’m certainly not advocating for building a ton of new industrial parks. Even when they’re designed with sustainability in mind, new facilities come with big carbon footprints, and they take up needed greenspace and may reduce biodiversity in the area. We can’t develop every single inch of land and have a healthy planet.

But I think it’s key to understand that you can’t overcome geographical hurdles—to either re-use or recycling logistics—until you’ve identified them. Once companies know what they’re up against, they can get really creative looking around at their neighbors and what infrastructure is available.

I think something that’s so interesting about the Kalundborg examples is the cross-industry nature of the project. Much of the time, those in the life science community tend to look within life sciences for solutions. It makes sense—no other sector is regulated in the same way. But for sharing by-products and resources, there may be great opportunities to collaborate with facilities far outside of healthcare.

In tackling climate change, all industries will have to get much more efficient at sharing resources to cut down on unnecessary waste and curb emissions.

Now, if you’ve found ways to get creative at your facility and have symbiotic or collaborative relationships with your neighbors, we at Healthcare Packaging want to hear about it. Reach out to me on LinkedIn with your story.

That’s all for today but stay tuned for ongoing coverage of this important topic. See you next time at Take Five for Healthcare Packaging!